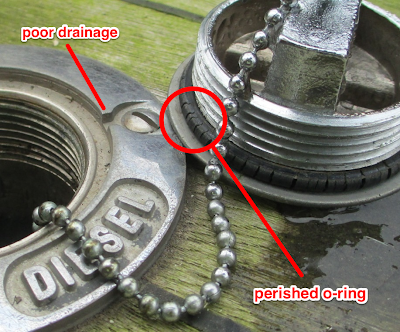

Diesel or Petrol fuel filler caps are often located on an exposed area of horizontal deck or cockpit floor, particularly on sailing yachts. I recently performed a pre-purchase survey on a Nauticat Pilothouse Ketch, located at Woolverstone

Marina, Ipswich. The image below shows the fuel filler cap & sealing O-ring of the starboard fuel tank of this motor-sailer. Note that the nitrile rubber has aged & hardened, resulting in numerous circumferential cracks in the O-ring, each one allowing moisture into the fuel tank. Additionally, the part of the fitting that was set into the deck was poorly designed, allowing sea water, rain water or dew to collect in the rebate that runs around the opening hole.

|

| Typical deck-mounted filler cap |

Prior to this discovery and during the survey of the rest of the vessel's fuel system, I had carefully inspected the glass-bowled primary fuel filter of each fuel tank. I noted that the colour of the liquid inside the starboard tank filter suggested that there may be water in the tank.

These were the recommendations made in the report:

1. It was found that the primary fuel filter for the starboard fuel tank had a layer of water at the bottom of the glass bowl. It is RECOMMENDED that any water in the bowls is tapped off from the primary filters for both fuel tanks. The fuel tanks should also be drained off and the contents checked for water contamination.

2. The two fuel tanks are refuelled via separate filler caps located on the port and starboard side decks. They were appropriately labelled with the text ‘diesel’. It was found that the O-ring seals that seal the filler caps were heavily perished. It is RECOMMENDED that the filler cap O-ring seals are replaced.

The new owner of the Nauticat was able to drain off two buckets of water from the starboard tank! He was lucky that there was no evidence of diesel fuel fungal growth in the tank as disel fuel with a high moisture content tends to encourage their growth.

In the UK, you can obtain new O-rings through Screwfix: www.screwfix.com/metric-o-ring-set You might not want to purchase a whole set of varying sizes just for this purpose, although it would be money well spent!